产品中心

Product center

IRB 6660预加工

ABB|

Robot version

|

Reach (m)

|

Payload

(kg)

|

Armload

(kg)

|

|

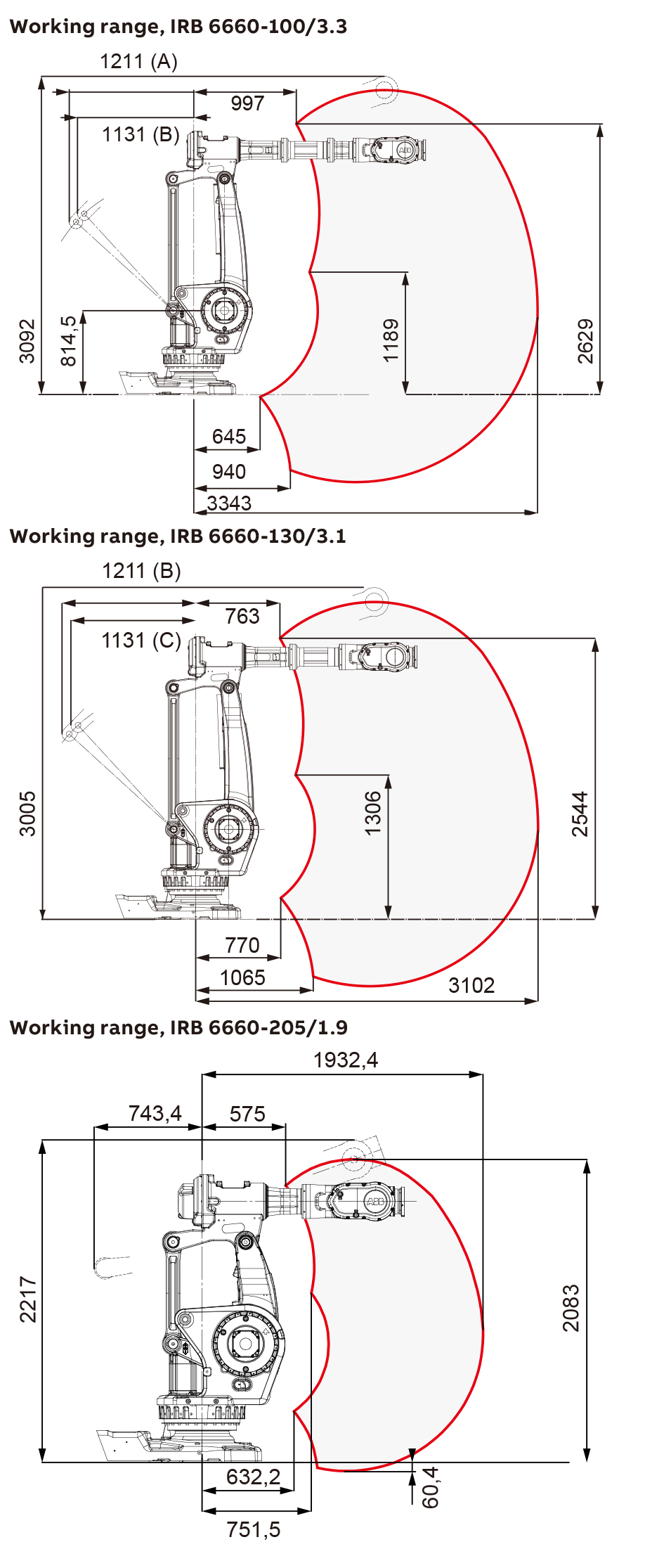

IRB 6660-100/3.3

|

3.35

|

100

|

20

|

|

IRB 6660-130/3.1

|

3.10

|

130

|

20

|

|

IRB 6660-205/1.9

|

1.93

|

205

|

15 + 500

on frame

|

|

Number of axes

|

6

|

||

|

Protection

|

Complete robot: IP 67, Optional

FoundryPlus and cable protection

(only IRB 6660-205/1.9)

|

||

|

Mounting

|

Floor

|

||

|

Controller

|

IRC5 Single Cabinet

|

||

|

Position

repeatability

|

|

|

IRB 6660-100/3.3

|

0.10 mm

|

|

IRB 6660-130/3.1

|

0.15 mm

|

|

IRB 6660-205/1.9

|

0.10 mm

|

|

Electrical Connections

|

|

|

|

Supply voltage

|

200-600 V, 50/60 Hz

|

|

|

Power consumption

|

2.4 kW

|

|

|

|

ISO Cube Max. velocity

|

Press tending

cycle Max.

velocity

|

|

IRB 6660-100/3.3

|

2.3 kW

|

4.7 kW

|

|

IRB 6660-130/3.1

|

3.1 kW

|

3.9 kW

|

|

IRB 6660-205/1.9

|

3.6 kW

|

-

|

|

Physical

|

|

|

|

Robot base

|

1206 x 798 mm

|

|

|

Robot weight

|

|

|

|

IRB 6660-100/3.3

|

1950 kg

|

|

|

IRB 6660-130/3.1

|

1910 kg

|

|

|

IRB 6660-205/1.9

|

1730 kg

|

|

|

Environment

|

|

|

|

Ambient temperature for mechanical unit

|

||

|

During operation

|

+5°C (41°F) to +50°C (122°F)*

|

|

|

During transportation and storage

|

- 25°C (13°F) to +55°C (131°F)

|

|

|

During short periods (max. 24 h)

|

up to +70°C (158°F)

|

|

|

Relative humidity

|

Max. 95%

|

|

|

Noise level

|

Max. 70-73 dB(A)

|

|

|

Safety

|

Double circuits with supervision,

emergency stops and safety functions,

3-position enable device

|

|

|

Extended safety

|

SafeMove2

|

|

|

Emission

|

EMC/EMI-shielded

|

|

|

Axis movement

|

Working range

|

Axis max. speed

|

||

|

-130/ 3.1

|

-100/ 3.3

|

-205/ 1.9

|

||

|

Axis 1 rotation

|

+180° to -180°

|

110°/s

|

110°/s

|

130°/s

|

|

Axis 2 arm

|

+85° to -42°

|

130°/s

|

130°/s

|

130°/s

|

|

Axis 3 arm

|

+120° to -20°

|

130°/s

|

123°/s

|

130°/s

|

|

Axis 4 rotation

|

+300° to -300°

|

150°/s

|

150°/s

|

150°/s

|

|

Axis 5 bend

|

+120° to -120°

|

120°/s

|

120°/s

|

120°/s

|

|

Axis 6 turn

|

+360° to -360°

|

240°/s

|

240°/s

|

190°/s

|