产品中心

Product center

IRB 6650S

ABB|

Robot version

|

Reach (m)

|

Handling capacity (kg)*

|

Center of gravity (kg)

|

Wrist torque (Nm)

|

|

Without LeanID

|

12

|

|

|

|

|

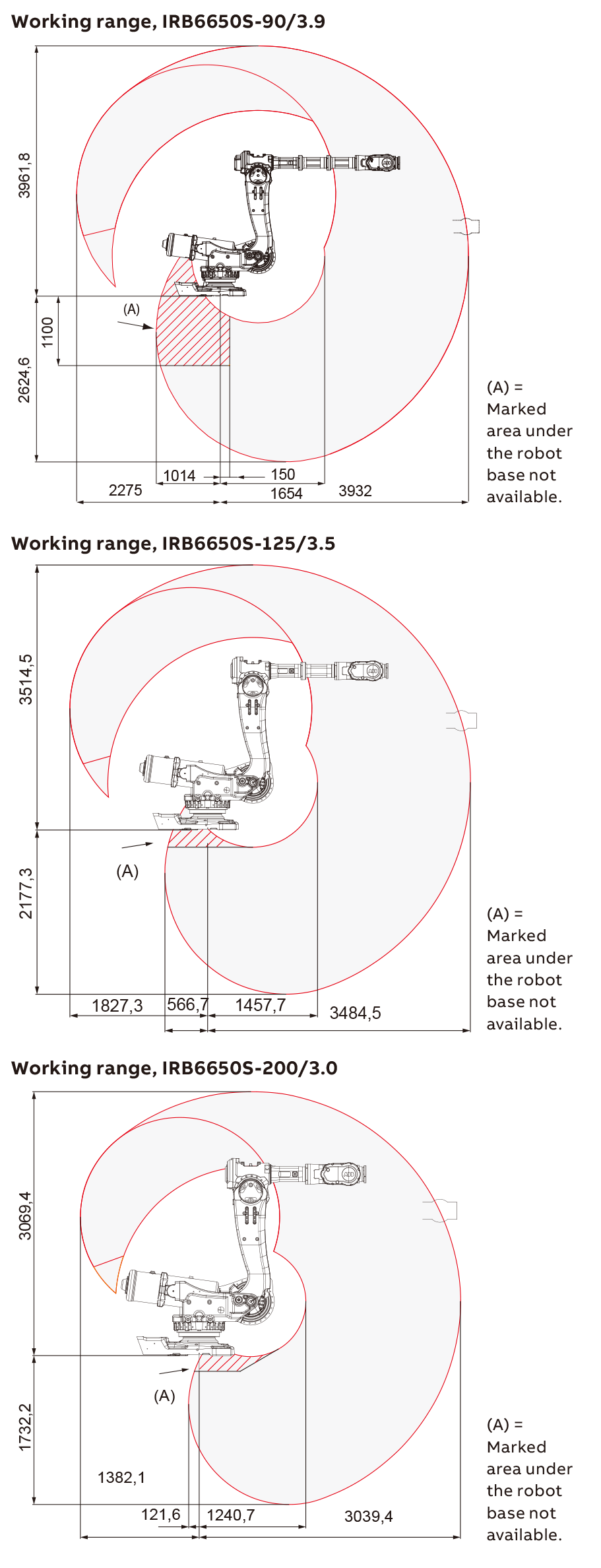

IRB 6650S-90/3.9

|

3.9

|

90

|

360

|

495¹

438² |

|

IRB 6650S-125/3.5

|

3.5

|

125

|

360

|

1037¹

526² |

|

IRB 6650S-200/3.0

|

3.0

|

200

|

365

|

1264¹

625² |

|

With LeanID

|

|

|

|

|

|

IRB 6650S-90/3.9*

|

Not available with LeanID

|

|||

|

IRB 6650S-125/3.5*

|

3.5

|

100

|

300

|

1259

|

|

IRB 6650S-200/3.0*

|

3.0

|

190

|

300

|

896

|

|

Number of axes

|

6

|

|||

|

Protection

|

Std: IP67. Option: Foundry Plus 2,

High pressure steam washable

|

|||

|

Mounting

|

Shelf

|

|||

|

Controller

|

IRC5 Single Cabinet

|

|||

|

Position

repeatability

|

Path

repeatability

|

|

|

IRB 6650S

|

0.15 mm

|

1.00 mm

|

|

Electrical Connections

|

|

|

Supply voltage

|

200-600 V, 50/60 Hz

|

|

Energy consumption

|

2.4 kW

|

|

Physical

|

|

|

Robot base

|

1136 x 864 mm

|

|

Robot weight

|

|

|

IRB 6650S-90/3.9

|

2275 kg

|

|

IRB 6650S-125/3.5

|

2250 kg

|

|

IRB 6650S-200/3.0

|

2250 kg

|

|

Environment

|

|

|

Ambient temperature for mechanical unit

|

|

|

During operation

|

+5 °C (41 °F) to +52 °C (122 °F)

|

|

During transportation and storage for short periods (max. 24h)

|

-25 °C (13 °F) to +55 °C (131 °F)

|

|

Relative humidity

|

Max. 95%

|

|

Noise level

|

Max. 73 dB (A)

|

|

Safety

|

Double circuits with supervision, emergency stops and safety functions, 3-position enable device

|

|

Extended safety

|

SafeMove2

|

|

Emission

|

EMC/EMI-shielded

|

|

Options

|

Foundry Plus 2, LeanID

|

|

Axis movement

|

Working range

|

Axis max. speed

|

|

Axis 1 rotation

|

+180° to -180°

|

100°/s

|

|

Axis 2 arm

|

+160° to -40°

|

90°/s

|

|

Axis 3 arm

|

+70° to -180°

|

90°/s

|

|

Axis 4 rotation

|

+300° to -300°

|

150°/s

|

|

Axis 5 bend

|

+ 120° to - 120°

|

120°/s

|

|

Axis 6 turn

|

+360° to -360°

|

235°/s

|